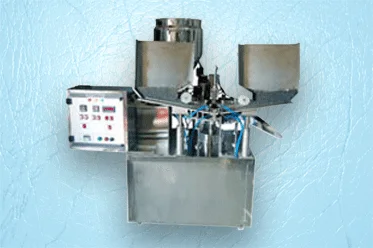

High Speed Multi Head Container Filling Machines

This multi head filling machine has diverse syringe type heads used for filling number of bottles or containers simultaneously. These filling machines are used for semi solid products like sauce, jams, balms, paste, creams and so on. The operations performed with the machine are automatic. The containers are filled up with the products so, if there are no containers the machine will stop working. Dripfree mechanism is used for filling the liquids or semi-liquids to avoid wastage of materials. Some of the salient features of the machine can be summed as below:

- ➤ It displays efficient operation at high levels.

- ➤ The operational part is totally noise free and vibration free.

- ➤ All operations are automatic except loading of containers on the conveyor belt. The machine will not work if there is no container.

- ➤ The range of a syringe will vary from 5 gms to 75 gms per syringe.

- ➤ All the parts of the machine are made up from high quality SS316 and SS304 steel material.These are Teflon coated easily detachable and simple for cleaning and maintenance.

- ➤ Thermo statically jacketed hopper is made optionally available.

We at harsh pharma and engineering as a manufacturer of high speed multi head container filling machines are obsessed with providing the best quality machines to our customers. We are working with the latest technology and infrastructure for designing part of the instrument so that our customers get a competitive edge with most modern techniques and solutions over the products. We have a dedicated team of quality technicians who are committed to provide quality products and services and work as per predetermined standards and norms. Due to our stringent controls, we have carved a good name for ourselves in the industry and are being followed by a large group of satisfied customers for our services. We offer our customers an economical and low budget package to suit their requirements and needs. Some of the reasons for our dignity in the market can be explained in brief as under:

- ➤ Our attractive policies and decent methods of business.

- ➤ Use of most modern technology in manufacturing of best quality machines.

- ➤ A good team of highly skilled and determined professionals having a passion to produce high quality products.

- ➤ A client receptive approach designed by us which allows interactive sessions from our customers related to the specifications of the products.

- ➤ A low cost budgeted structure that will favor the policies of our customers.

- ➤ High quality machines manufactured and delivered in a timely manner.

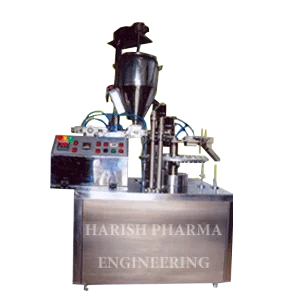

Single & Double head twelve station, semi & automatic, Aluminium or lami and plastic tube filling , sealing, coding and cutting machine.

| Range | Single head 5 to 100gm 30 tube double head 5 to 50gm Tube. |

| Single | S.S. Syringe range 5 to 25, 25 to 50, 50 to 100 |

| Double | S.S. Syringe range 5 to 25, 25 to 50 |

| Required | As jacketed hopper and S.S. stirrer. all contact parts are of teflon & SS 304/316 qualities required. |

All operations are automatic except loading of containers on conveyor belt. Automatic collection of filled containers on collection tray / conveyor. If there is no container the machine will not work.

Range: 5 gms to 22 gms in one syringe. 30 gms to 75 gms in one syringe.

Speed : 5 gms to 25 gms 60 to 90 Containers / min. 30 gms to 75 gms 45 to 60 gms Containers

All contact parts are easily detachable for cleaning/sterilization. All contact parts are of Teflon and SS 304 / 316 quality as required.

Thermo statically controlled jacketed hopper. Optionally available in SS Stirrer.

Optionally available in rotary table for feeding of containers of conveyor belt, supplied only on customers requirement. This machine is easy to maintain & is also simple to operate.